EMI Shielding Methods for Flex PCB Designs

- Flex Plus Tech team

- Nov 17, 2025

- 4 min read

Electromagnetic interference (EMI) has become a familiar challenge in flexible PCB design—especially as devices get thinner, faster, and more compact. There’s no single “best” way to block EMI, but several practical shielding approaches have proven reliable across consumer electronics, automotive, medical, and aerospace applications.

Among all available choices, three EMI shielding methods stand out as the most widely used and most flexible-friendly:copper layers, shielding films, and silver epoxy ink. The following sections walk through what each method offers, how they behave in real flex-circuit applications, and where engineers usually apply them.

1. Copper Layers

The Classic, High-Performance Shield

Copper is always the first method designers think of. It offers the strongest shielding and is compatible with almost any high-speed or RF application.

Why it's effective

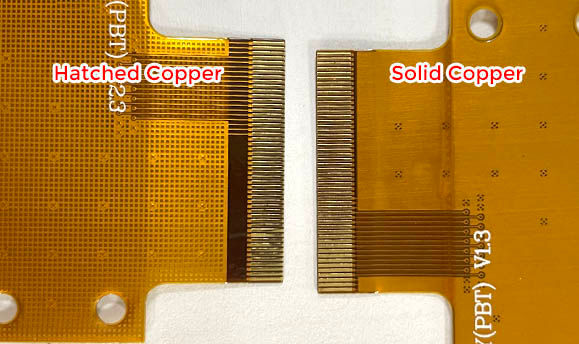

Copper has excellent electrical conductivity, so it reflects and absorbs EMI efficiently. In flexible PCBs, it can appear as:

A full copper layer dedicated for shielding (best choise)

Copper mesh for lighter weight

A copper foil laminated onto the outer surface

Where engineers use it

High-speed flex sections

FPCs carrying sensitive analog or RF signals

Automotive and aerospace modules that require guaranteed EMC performance

What to keep in mind

Copper shielding improves performance, but it also increases material cost, stiffness, and stack-up thickness—so it's commonly used when EMI performance is the top priority.

2. Shielding Film

The Most Popular Choice for Thin Flex Designs

Shielding film has become the default shielding option for many consumer electronics because it’s thin, flexible, and relatively cost-efficient.

A typical film structure includes:

A layer of aluminum or copper

Conductive adhesive

A PET or PI outer layer

Why people choose it

Very thin, ideal for ultra-slim flex cables

Good flexibility even during repeated bending

Lower weight and cost compared with full copper layers

Easy to laminate during flex PCB manufacturing

Common applications

Mobile devices and foldable electronics

Wearables

Camera modules

Display interconnects

Shielding film doesn’t provide the “absolute best” EMI performance like solid copper, but for most consumer-grade electronics, it delivers more than enough protection with much better mechanical flexibility.

3. Silver Epoxy Ink

Lightweight and Bend-Friendly

Silver epoxy ink (conductive ink) is another flexible-friendly shielding option. Instead of using a metal sheet, a thin layer of conductive ink is printed on the flex surface or coverlay.

Why engineers like it

Extremely thin and lightweight

Very high flexibility — good for dynamic-flex designs

Suitable for large-area shielding without adding much stiffness

Cost-effective compared with metal layers

Things to consider

Not as strong as copper in terms of EMI performance

Must be printed with stable process control to avoid cracks

Best for low-to-medium EMI environments

Where it's commonly used

Smart wearable bands

Soft medical devices

Consumer devices with lightweight flex circuits

Low-voltage interconnects

Silver ink gives a balanced combination of low cost, bendability, and easy application.

Other EMI Shielding Options

While the three methods above cover most flexible PCB needs, other approaches still appear in certain applications. These are usually supplementary or used together with the main methods:

Grounded guard traces / ground pour

Simple, effective, and commonly used to reduce noise coupling around sensitive lines.

Metalized coverlay

A PI film coated with metal — good for flexible but rugged designs.

Shielding cans in rigid-flex circuits

Used when the rigid section carries RF modules or antennas.

Conductive tapes

Handy for prototyping or simple EMC fixes but rarely used as a long-term production solution.

These methods help, but they are usually not the primary shielding strategy for modern flexible PCB boards.

EMI Shielding Methods Comparison

Shielding Method | Pros | Cons |

Copper Layers | • Most effective shielding method • Controlled-impedance capable • Best for high-density component areas • Suitable for all flex and rigid-flex PCB designs • Can be extended under stiffeners | • Higher cost and reduced flexibility • Significant flex-thickness increase • Mesh copper improves bendability but reduces shielding • Added process steps and materials increase cost • Limited use on >2-layer flex circuits due to bend requirements • Takes additional circuit area (extra vias for SMT grounding) |

Shielding Film | • Very effective shielding—close to copper • Most cost-effective and flexible solution • Can be used in component areas with some limits • Suitable for both flex and rigid-flex • Most used method for non-impedance-controlled designs • Wide variety of films available | • Not recommended for controlled-impedance designs • Larger impedance tolerance and dielectric-thickness variation • Limited in high-density component areas (film thickness constraints) • Exposed ground circuit at flex outline • Stiffeners cannot be laminated directly (friction-resistant surface) • Requires PSA for stiffener attachment |

Silver Ink | • Effective EMI shielding • Lower cost than copper • More flexible than copper shield layers • Can be extended under stiffeners • Can be used (with limits) on higher-layer flex designs • Long-established method used for decades | • Many additional process steps (1-2 print + bake cycles) • Requires 1-2 extra coverlay layers • Reduced bend capability due to added thickness • Not recommended for controlled-impedance circuits • Difficult to achieve required dielectric thickness • Not compatible with rigid-flex PCB structures • Very limited for high-density areas. |

Conclusion

Flex PCB EMI shielding doesn’t rely on one universal solution. Copper layers, shielding film, and silver epoxy ink each offer different benefits — whether you need top-tier EMC performance, ultra-thin construction, or excellent bend reliability.

Learn more about flexible PCBs, from key design considerations to full fabrication processes.

Comments