Solid vs. Hatched Copper in Flex PCB Design

- Flex Plus Tech team

- Mar 13, 2025

- 2 min read

Updated: Nov 10, 2025

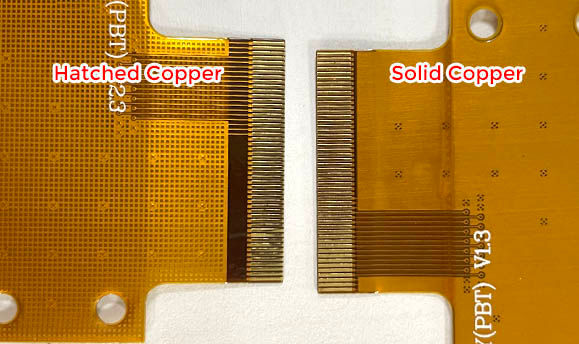

In flexible PCB design, the choice of copper fill has a direct impact on electrical performance, flexibility, EMI shielding, and durability. Engineers usually choose between solid copper and hatched copper depending on the application. At Flex Plus, we often see design trade-offs between these two methods. Let’s break down their differences with real-world considerations.

What Is Solid Copper Fill?

Solid copper means a continuous copper layer without gaps.

Advantages:

Excellent Conductivity – Carries higher currents, ideal for power layers.

Strong EMI Shielding – Provides superior protection in RF and high-frequency circuits.

Better Heat Dissipation – Distributes heat evenly across the board.

Disadvantages:

Limited Flexibility – More prone to cracking when bent.

Manufacturing Challenges – Requires careful etching to avoid uneven copper thickness.

Slightly Heavier – May add unnecessary weight in lightweight applications.

Best Use Cases:

Power distribution layers

RF and wireless communication devices

High-performance automotive and aerospace electronics

What Is Hatched Copper Fill?

Hatched copper uses a grid-like structure instead of a solid plane, improving flexibility.

Advantages:

Greater Flexibility – Prevents copper cracks in bending zones.

Lightweight Design – Copper fill rate ranges 30%–70%, making circuits thinner.

Easier Manufacturing – Reduces etching stress and improves yield.

Disadvantages:

Lower Conductivity – Not suitable for high-current paths.

Weaker EMI Shielding – Grid gaps allow more interference.

Reduced Heat Dissipation – Less copper surface area to spread heat.

Best Use Cases:

Wearable devices and foldable displays

Lightweight aerospace or medical electronics

Low-power circuits such as touch sensors and control panels

Solid vs. Hatched Copper Flex PCB: How to Decide?

Choose Solid Copper if…Your flex PCB needs high current carrying capacity, strong EMI shielding, or better thermal management.

Choose Hatched Copper if…Your design requires frequent bending, lightweight structure, or cost-effective low-power performance.

Many engineers today use hybrid designs: solid copper in power/EMI-sensitive areas, hatched copper in flexible sections.

FAQ: Flex PCB Copper Fill

Q1: Does hatched copper reduce EMI shielding?

Yes. Since hatched copper has gaps, it is less effective at blocking EMI compared to solid copper.

Q2: Can solid copper be used in wearable devices?

Not recommended. Solid copper increases stiffness and may crack under repeated bending.

Q3: Which option is more cost-effective?

Hatched copper is often easier to manufacture, but solid copper may be more cost-efficient in high-power circuits due to fewer failures.

Conclusion

The right copper fill choice depends on your application’s priorities—current capacity, bending durability, EMI performance, or weight reduction. At Flex Plus, we often recommend solid copper for high-power and EMI-sensitive designs, while hatched copper works best for flexible, lightweight devices.

For more details about flexible PCB manufacturing, visit our Flexible PCB Guide.

If you’re unsure which approach fits your project, our engineering team can review your design and suggest the best copper fill strategy.

👉 Contact Flex Plus today to discuss your flex PCB design needs.

Comments