What Is 94V-0 on a Flexible Circuit Board?

- Flex Plus Tech team

- Oct 16, 2025

- 3 min read

94V-0 on a flexible circuit board refers to a UL flammability rating that measures how resistant the board’s material is to fire. When a flexible PCB is labeled as 94V-0, it means the substrate has passed the UL 94 vertical burn test, proving that it can self-extinguish within 10 seconds after flame exposure and does not produce flaming drips. In short, a 94V-0 flexible circuit board is a flame-retardant FPC designed to meet the highest safety requirements in electronic manufacturing.

Understanding the UL 94V-0 Standard

The UL 94V-0 standard is widely recognized across the electronics industry.

“94” refers to the UL test standard number.

“V” indicates the vertical burn test orientation.

“0” means the highest level of fire resistance under this test.

Materials that achieve this rating stop burning within 10 seconds and produce no flaming particles. That’s why UL 94V-0 is the preferred safety grade for modern flexible circuit board materials.

Why 94V-0 Matters in Flexible PCB Manufacturing

A 94V-0 flexible circuit board is not just about safety; it also represents material stability, reliability, and compliance.

Fire resistance – Helps prevent the spread of flame in high-density electronics.

Heat stability – Withstands soldering, reflow, and lamination temperatures.

Regulatory compliance – Many industries such as automotive, aerospace, and medical electronics require UL 94V-0 materials.

Reliability – Maintains electrical insulation even under thermal stress.

These advantages make 94V-0 flexible circuit boards the standard choice for products that demand both lightweight design and high reliability.

How the UL 94V-0 Test Works

The UL 94V-0 test exposes a vertically mounted material sample to a small flame for 10 seconds, removes the flame, and measures how long it continues to burn. To pass:

Each specimen must extinguish within 10 seconds.

Total after-flame time for five samples must not exceed 50 seconds.

No flaming drips are allowed.

In FPC manufacturing, polyimide (PI) base films usually meet or exceed 94V-0 performance when paired with flame-retardant adhesives or coverlays.

Common Materials Used in 94V-0 Flexible Circuit Board

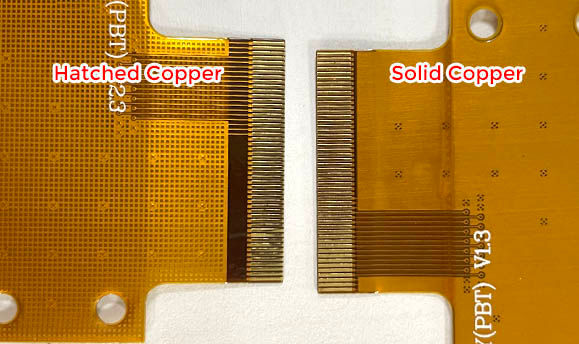

Manufacturers often use UL-recognized polyimide materials because they combine high flexibility with excellent thermal performance.Typical 94V-0 materials include:

Polyimide (PI) copper-clad laminates

Adhesiveless laminates for thinner and lighter designs

Flame-retardant PET films for cost-sensitive projects

FR-series base films (for rigid-flex applications)

Each component—base film, adhesive, coverlay, and stiffener—must meet the same UL 94V-0 standard to ensure full compliance.

Insights from a Flexible PCB Manufacturer

From a manufacturer’s perspective, achieving and maintaining the 94V-0 standard is not just a matter of choosing the right material—it’s about controlling every production stage.

At Flex Plus, for example, we focus on the following key points during manufacturing:

Material Traceability – Every batch of polyimide film and adhesive is sourced from UL-recognized suppliers with traceable certification numbers.

Lamination Process Control – Temperature and pressure must be precisely regulated to prevent resin decomposition, which could affect flame resistance.

Adhesive Selection – For multilayer flexible PCBs, we use low-flow, flame-retardant adhesives that maintain bonding strength without sacrificing 94V-0 compliance.

Surface Treatment – During processes like immersion gold or ENIG, the heat exposure is monitored to avoid microcracks that may influence thermal stability.

Internal UL Audits – Our production follows UL inspection protocols, ensuring that every shipment of 94V0 flexible circuit boards meets consistent quality and safety standards.

This manufacturer-level control is what makes 94V0 flexible circuit boards truly reliable in real-world applications—not just on paper.

How to Verify a Board’s 94V-0 Certification

To confirm if your FPC meets UL 94V-0, you can:

Check for the UL Recognized Component mark on the product.

Request the UL file number from your PCB supplier.

Search the UL online database to verify certification validity.

As a certified flexible PCB manufacturer, we always include this documentation in customer reports to ensure compliance in every project.

Design Tips for Engineers

When designing a 94V0 flexible circuit board, engineers should:

Choose UL-approved PI laminates and matching flame-retardant coverlays.

Use high-temperature-resistant stiffeners to maintain structural integrity.

Avoid overexposure to heat during soldering or reflow.

Keep clear labeling of UL certification for audit or end-customer inspection.

Good design combined with factory-level process control guarantees both performance and compliance.

Conclusion

In conclusion, 94V-0 flexible circuit boards represent the perfect balance of safety, reliability, and manufacturability. The UL 94V-0 rating ensures that the material self-extinguishes quickly, preventing potential hazards while maintaining electrical performance.

From a factory perspective, achieving 94V-0 compliance requires more than materials—it demands strict process management and certification traceability at every stage. That’s why experienced manufacturers like Flex Plus ensure that each FPC we produce meets UL 94V-0 requirements, providing our customers with safe, high-quality, and globally compliant flexible circuit solutions.

The angle of your article of FPC is very good!