Carbon Ink PCB Solutions for Electronics and Wearables

- Flex Plus Tech team

- Aug 28, 2025

- 3 min read

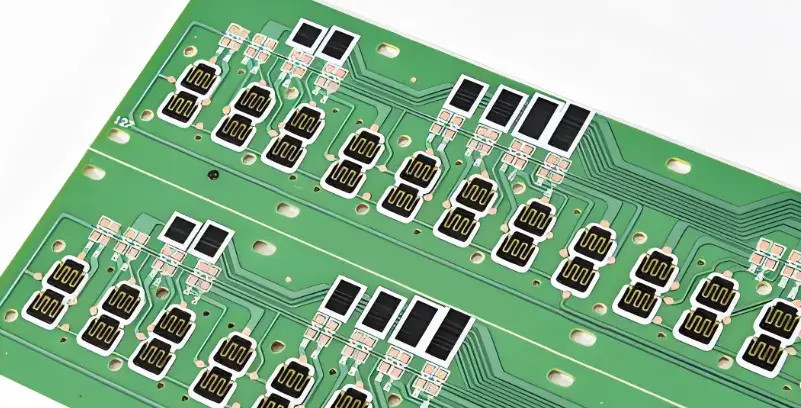

What is a Carbon Ink PCB?

A carbon ink PCB is a printed circuit board where conductive carbon ink is applied to pads or traces, usually through screen printing. The cured carbon layer serves as a protective and conductive coating, offering a cost-effective alternative to metal finishes like gold plating.

According to market research from IDTechEx, the global conductive ink market—including carbon-based inks—is projected to surpass $3.5 billion by 2026, driven largely by flexible and wearable electronics. This shows that Carbon Ink PCB technology is becoming a vital component in next-generation devices.

Advantages of Carbon Ink in FPC boards

Compared with traditional surface finishes, carbon ink offers:

Cost Efficiency – Gold plating can be up to 5–10 times more expensive than carbon ink finishing.

Wear Resistance – Carbon layers endure repetitive mechanical contact, making them ideal for keypads and switches.

Stable Conductivity – Resistance typically ranges between 10–50 Ω/sq, providing reliable performance for low-voltage circuits.

Corrosion Protection – Carbon coatings reduce copper oxidation, extending printed circuit board service life.

Versatility – Works well across automotive, medical, and consumer electronics.

Common Applications of Carbon Ink PCB

Keypads & Membrane Switches – Durable under millions of actuations.

Remote Controls & Consumer Electronics – Cost-effective for mass-market devices.

Automotive Electronics – Widely used in dashboards and climate-control switches.

Medical Devices – Compact, lightweight, and biocompatible for diagnostics.

Industrial Control Systems – High endurance under continuous operation.

How Carbon Ink Printed Circuit Boards are Manufactured

The process includes:

Copper Pattern Formation – Standard PCB fabrication.

Carbon Ink Printing – Screen-printing carbon conductive ink onto selected pads.

Curing Process – Heat curing at 150–180°C for 30–60 minutes to ensure adhesion.

Surface Finishing – Optional HASL, ENIG, or OSP for other areas.

Testing – Resistance, adhesion, and durability are verified according to IPC standards.

Carbon Ink vs. Gold Plating

Feature | Carbon Ink PCB | Gold-Plated PCB |

Cost | Low | High |

Wear Resistance | High | High |

Conductivity | Moderate | Excellent |

Corrosion Proof | Good | Excellent |

Best Use | Keypads, heating, wearables | High-frequency & premium devices |

Carbon Ink Circuit with TPU: Expanding Possibilities

When carbon ink circuits are combined with TPU, they gain flexibility and comfort—qualities essential for wearable electronics.

Key Features of Carbon Ink + TPU Technology:

Thin & Lightweight – Circuit thickness can be less than 0.3 mm.

Controlled Heating – Carbon ink’s resistance enables stable heating at 35–60°C, safe for human contact.

Biocompatibility – TPU is skin-friendly, making it ideal for medical and wearable use.

Applications Include:

Wearable heating devices

Smart textiles

Sports recovery equipment

Medical therapy belts

Flexible sensors for IoT devices

Flex Plus Case Study: Carbon Ink Printed Circuit on TPU Heating Belt

At Flex Plus, we integrated carbon Ink circuit on TPU into a wearable heating belt.

Design: Carbon ink was screen-printed on TPU film, forming heating circuits with uniform resistance.

Performance: When powered at 5V–12V, the circuit generated consistent heat between 30–50°C, suitable for safe skin contact.

Application: Used in a waist support belt, the product provided gentle heat therapy to the lumbar area, improving comfort and circulation.

Result: Compared with traditional wire-based heating pads, this solution was 30% lighter, 40% thinner, and more flexible, making it ideal for long-term wearable use.

This project highlights how Carbon Ink + TPU technology is enabling a new generation of wearable healthcare and lifestyle products.

Whether you're developing a new product or refining an existing design, FlexPlus FPC can provide the ideal flex PCB solutions for your needs.

Comments