Reliable Flex PCB Design for Syringe Pumps

- Flex Plus Tech team

- Jan 23, 2025

- 2 min read

Updated: Aug 26, 2025

In the medical electronics industry, precision and reliability are critical. Among medical devices, syringe pumps require extremely accurate electronic control to ensure safe and stable drug delivery. Any design flaw in the printed circuit board can lead to electromagnetic interference (EMI), unstable signals, or even risks to patient health.This is why flexible PCBs have become the preferred solution in syringe pumps and other medical devices. Their flexibility, durability, and EMI management capabilities help meet strict healthcare requirements.

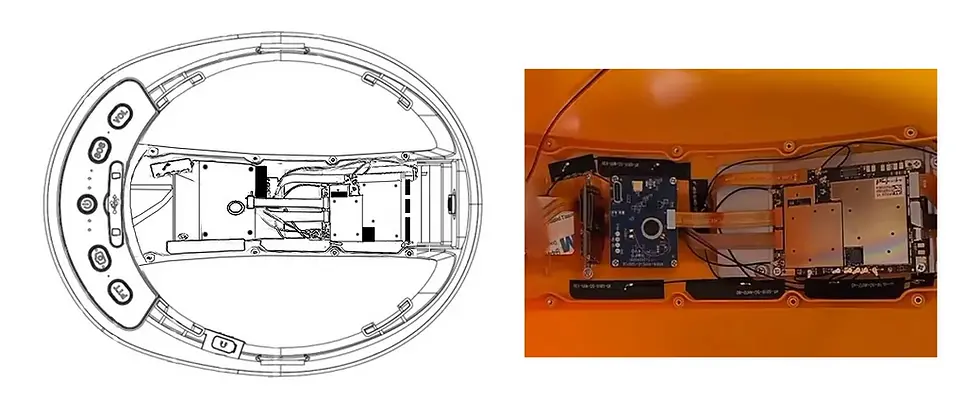

Flex PCB Design for Syringe Pumps

A syringe pump places high demands on its internal circuit boards. To achieve stability, signal accuracy, and EMI shielding, a laminated Flex PCB structure is used.

Top and Bottom Layers: Protective Coverlay

Insulates and protects copper circuits

Prevents short circuits and mechanical damage

Extends service life of the board

Middle Layer: Silver Paste for EMI Shielding

Provides strong electromagnetic compatibility (EMC)

Reduces external and internal interference

Ensures stable operation of drug delivery systems

Double-Sided FCCL: High-Density and Reliable

Circuit etched on one side, continuous copper layer on the other

Copper plane reduces EMI and stabilizes signal transmission

Supports compact design within limited device space

EMI Management in Medical Equipment

Electromagnetic interference is a major challenge in medical electronics. It can:

Disrupt syringe pump operation

Affect the accuracy of drug injection

Interfere with other hospital devices

Flex PCB solutions for EMI shielding include:

Silver paste shielding layer for noise reduction

Large copper layers to block interference

Stable transmission paths for accurate signals

Advantages of Flex PCB in Medical Devices

High Reliability – Withstand long-term use in clinical environments

Stable Signal Transmission – Ensures precise drug dosage control

Compact and Flexible – Adapts to limited internal space of syringe pumps

EMI Shielding – Reduces risk of malfunction caused by interference

Flex Plus Medical PCB Solutions

At Flex Plus, we specialize in manufacturing medical-grade Flex PCBs with strict quality control. Using advanced lamination, fine etching, and selected FCCL materials, we provide:

Reliable EMI management

Stable performance under clinical conditions

Custom Flex PCB solutions for syringe pumps, monitors, and other medical devices

If you are developing medical electronics, Flex Plus can support your project with precision PCB manufacturing that ensures safety, stability, and compliance.

Contact us today to discuss your medical device PCB requirements.

Comments