Flex PCB in Smart Safety Helmets

- Flex Plus Tech team

- Sep 1, 2025

- 3 min read

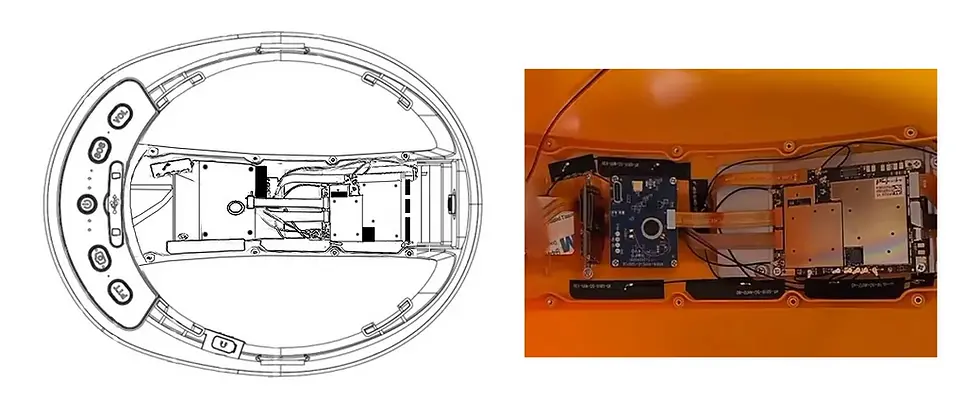

A decade ago, helmets were seen purely as protective gear. Today, whether on a racetrack, deep underground, or in orbit, helmets are expected to do much more. They house sensors, displays, radios, lighting, and monitoring systems—all within a very limited volume. Making these features possible without adding unnecessary weight or wiring complexity has pushed many designers toward flexible printed circuits.

Why Flexible Circuits Work Well in Helmets

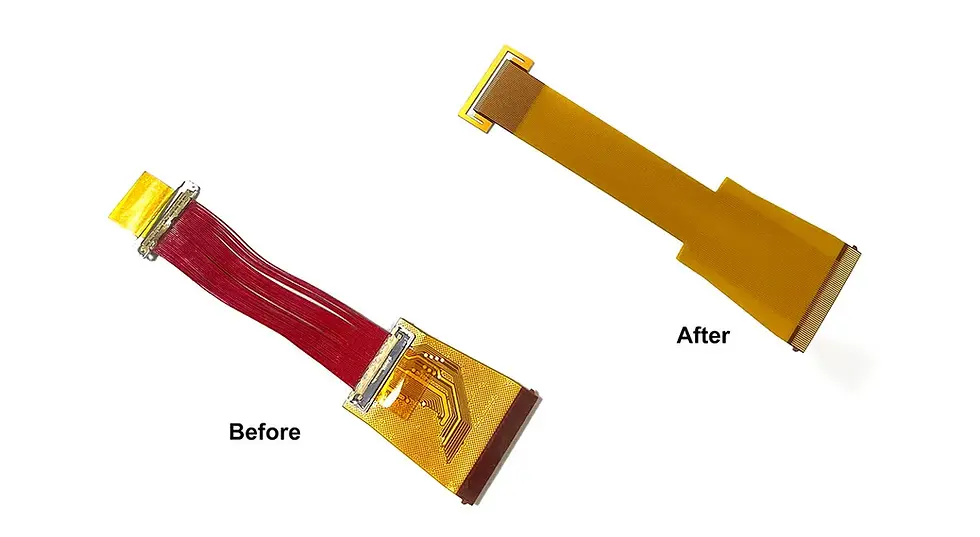

Inside a helmet, every gram matters, and space is always at a premium. Running bundles of wires or fitting multiple rigid boards is often impractical. Flexible PCBs solve several of these challenges:

They bend and follow the curved inner surface of a helmet.

They reduce bulk, replacing harnesses with thin copper traces.

They hold up against vibration, impact, and temperature swings.

In practice, a single helmet often uses several different FPCs—some short jumpers between boards, others routing signals across longer paths. This modular approach keeps electronics compact and reliable, even in demanding environments.

Where Flex PCB Boards Are Being Used

Motorsport: Professional racing helmets may carry a small display in the visor, biometric sensors, and comms systems to the pit crew. Flexible interconnects allow all of this without adding extra weight that could strain the driver’s neck.

Mining: Underground helmets often integrate gas detection sensors, safety lamps, and wireless links. Circuits must survive dust, humidity, and mechanical abuse. Double-sided or rigid-flex circuit boards are often chosen for their durability.

Space: Astronaut helmets represent one of the harshest electronic environments. Circuits have to function reliably in vacuum and under large thermal shifts. Multilayer flex designs, with shielding and redundant paths, are typically used to support oxygen monitoring, comms, and visor-mounted HUDs.

Construction & Industrial Safety: With the rise of connected PPE, more helmets now carry cameras, GPS, or IoT modules. Flexible PCBs simplify integration and cut down assembly complexity.

These examples show that flex PCB usage in helmets is not limited to a single industry. Any environment where compact, reliable, and multifunctional electronics are needed can benefit from flexible circuits.

Types of Flex PCB in Helmet Design

The choice of FPCB depends less on the helmet type and more on the function and complexity of the electronics. Helmets may include:

FPC Type | Typical Use in Helmets | Advantages | Considerations / Limitations |

Single-layer | Simple LED circuits, small sensors, indicator lights | Lightweight, low cost, easy to manufacture | Limited routing, not suitable for high-density signals |

Double-sided | Medium complexity modules: comms circuits, lighting, medium sensor arrays | Higher routing density, allows ground planes, moderate signal integrity | Slightly thicker, more expensive than single-layer |

Multilayer | Complex electronics: HUD, oxygen monitoring, multiple sensors, EMI-sensitive circuits | Supports high signal density, shielding, redundancy | Highest cost, requires careful thermal and mechanical design, more complex assembly |

Design note: Many helmets combine different flex PCB types to optimize weight, space, cost, and reliability. Single-layer circuits handle peripheral signals, double-sided circuits tackle moderate complexity, and multilayer circuits manage high-density or shielding-sensitive paths.

Key Reliability Considerations

When designing helmet flex PCB, engineers focus on metrics such as:

Bending cycles – circuits often need to survive over 100,000 flexes.

Operating temperature – typically from –40 °C to +125 °C.

Copper thickness – balancing flexibility with current-carrying capacity.

Surface finish and materials – ensuring long-term solder joint integrity.

In critical sectors like aerospace or mining, these considerations are essential for meeting safety standards.

Final Thoughts

Flexible circuits have become the backbone of smart helmets, enabling more compact, multifunctional, and reliable electronics. From motorsport to space exploration, flexible PCB boards allow engineers to integrate displays, sensors, communications, and lighting without sacrificing safety or comfort.

If you are exploring flex PCB solutions for smart helmet projects or other wearable electronics, our team can provide design guidance and manufacturing expertise tailored to your application.

Comments