Flex PCB Replacement of Wire Harness

- Flex Plus Tech team

- Aug 11, 2025

- 2 min read

In modern product design, the way components connect can greatly affect device size, weight, reliability, and manufacturing cost. A flex PCB replacement of wire harness offers a compact and efficient solution that optimizes these factors.

Original Design Challenges and Inefficiencies

Traditionally, products used separate wire harnesses combined with flexible PCBs. This two-part design created inefficiencies:

Bulky Wiring: wire harnesses consumed valuable internal space.

Complex Assembly: Connecting harnesses to PCB boards added extra assembly steps.

Reliability Risks: Additional connectors increased failure points due to vibration or stress.

Higher Costs: Multiple components raised procurement and labor expenses.

Our Engineering Approach to Product Optimization

Our solution replaces the bulky wire harness and connector with a single-piece flexible PCB. This integration streamlines the design by:

Direct Signal Integration: Conductive traces replace separate wires within the flexible PCB.

Connector Elimination: Removing connectors reduces mechanical failure points.

Custom PCB Shape: Tailored for easy bending and routing inside the device.

Flex PCB Replacement of Wire Harness: Key Benefits

Space and Weight Reduction

Eliminating wire harnesses frees internal space and cuts component weight, ideal for compact, portable devices.

Faster and Simpler Assembly

Removing harness connections reduces assembly complexity, boosting production efficiency.

Improved Reliability

Fewer connectors mean fewer mechanical interfaces that could loosen or fail, enhancing long-term device durability.

Cost Savings

Material and labor costs decrease by using one integrated flexible PCB instead of multiple parts.

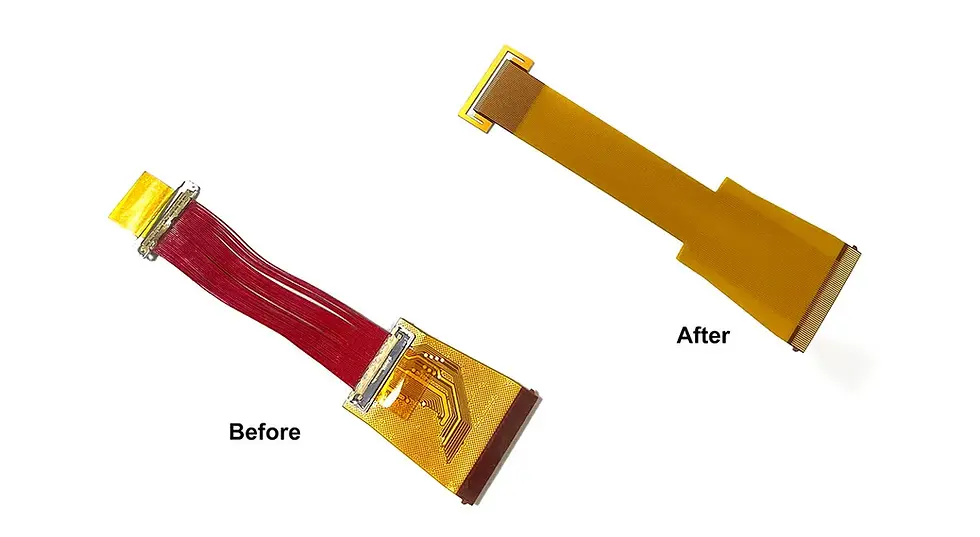

Visual Comparison: Before and After

Before: Separate wire harness (red wires) plugged into flexible PCB via connectors, increasing assembly steps and complexity.

After: One-piece flexible PCB replaces harness and connectors, simplifying routing and improving durability.

How Flex PCB Replacement of Wire Harness Improves Reliability

Replacing wire harnesses with flexible PCBs benefits manufacturing by:

Simplifying supply chains with fewer parts

Enhancing quality control via single-piece inspection

Accelerating production scalability with reduced assembly time

Increasing long-term product reliability

Expertise in Flexible PCB Solutions

With deep experience in flexible and rigid-flex PCB manufacturing, innovative flex PCB replacement of wire harness solutions can transform bulky, multi-component designs into sleek, efficient products suitable for automotive, aerospace, consumer electronics, and medical industries.

If you’re looking to simplify your product’s internal wiring and enhance overall performance with a one-piece flexible PCB solution, now is the perfect time to explore the benefits of flexible PCB replacement of cable harness. Contact Flex Plus to discuss your project requirements or request a quote.

Learn more about FPC cables and FFCs to understand how this technology can upgrade your designs: https://www.flexplusfpc.com/post/what-are-fpc-cable-and-ffc

Comments