ENIG vs Hard Gold for Flexible PCB:Performance, Reliability and How to Choose

- Flex Plus Tech team

- 1 day ago

- 4 min read

ENIG vs hard gold for flexible PCB is a common engineering decision when selecting surface finish for flexible circuit designs. Surface finish selection has a direct impact on reliability, bending performance, and long-term durability in flexible PCB applications. Among the available options, ENIG (Electroless Nickel Immersion Gold) and Hard Gold (Electroplated Gold) are two commonly specified finishes — but they serve very different purposes in FPC design.

In flexible PCB manufacturing, ENIG and hard gold are used for different functional requirements. The correct choice depends on mechanical stress, contact durability, and assembly process conditions.

1. What Is ENIG in Flexible PCB?

ENIG is a chemical surface finish consisting of:

Electroless nickel layer (typically 3–6 µm)

Thin immersion gold layer (0.05–0.1 µm)

Characteristics in FPC:

Flat surface ideal for fine-pitch SMT

Good solderability

Moderate cost

Limited wear resistance

Nickel layer adds some rigidity locally

In flexible PCB applications, ENIG is commonly used for:

SMT pads

BGA areas

Fine-pitch components

Medical and consumer electronics

However, because ENIG contains a nickel layer, placing it in high dynamic bending areas requires careful design consideration.

2. What Is Hard Gold in Flexible PCB?

Hard gold is an electrolytic plating process:

Thicker nickel layer

Thick gold layer (0.5–2.0 µm typical)

Gold alloyed with cobalt or nickel for hardness

Key characteristics:

High wear resistance

Excellent durability under repeated insertion

Higher cost

More rigid than ENIG

In flexible PCBs, hard gold is typically used for:

Gold fingers

Edge connectors

Repeated insertion contacts

Industrial and automotive interfaces

Hard gold is not normally used for SMT pads due to cost and process complexity.

3. ENIG vs Hard Gold in Flexible PCB Applications

The real difference appears when flexibility and mechanical stress are involved.

Factor | ENIG | Hard Gold |

Primary use | SMT pads | Gold fingers / connectors |

Wear resistance | Moderate | High |

Nickel thickness | Medium | Thick |

Impact on flexibility | Lower | Higher |

Suitability in bending area | Limited | Not recommended |

Cost | Medium | Higher |

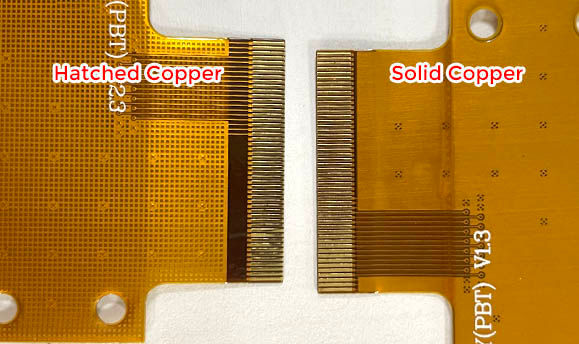

Flexibility Impact

Both finishes include nickel, but hard gold typically involves:

Thicker nickel

Thicker gold

Electroplated structure

This makes hard gold areas significantly stiffer than standard ENIG areas.

In dynamic bending applications, thick nickel plating increases the risk of:

Micro-cracks

Delamination

Copper trace fracture at transition zones

4. Can Hard Gold Be Used in Bending Areas?

In practice, we do not recommend placing hard gold in dynamic bend regions.

Reasons:

Nickel layer reduces flex endurance

Plating stress may concentrate at pad edges

Transition between plated and non-plated zones can create stress points

If gold fingers are required in a flexible PCB:

Keep them outside bending areas

Add stiffener support

Control transition radius carefully

For high-flex applications (wearables, medical probes, robotics), surface finish placement must be considered during stack-up design.

5. Reliability Considerations in Real Manufacturing

From a manufacturing perspective:

ENIG Risks

Black pad (if process not controlled)

Nickel brittleness under repeated flex

Thickness uniformity control required

Hard Gold Risks

Higher internal stress

Plating thickness variation

Reduced bending cycle life

The choice of flexible PCB surface finish type should not be based solely on corrosion resistance—the mechanical environment is equally important.

6. How to Choose Between ENIG and Hard Gold for Flexible PCB

Choose ENIG if:

The area is used for SMT assembly

Fine-pitch components are required

Moderate mechanical stress

Cost control is important

Choose Hard Gold if:

Repeated insertion is required

Connector wear resistance is critical

Edge contact reliability is a priority

Avoid both in:High dynamic bending zones(unless mechanically reinforced)

7. Practical Design Advice

When designing flexible PCB with gold finishes:

Separate bending zones and contact zones

Control nickel thickness

Avoid abrupt copper-to-plating transitions

Consider stiffener support for gold finger areas

Surface finish is not just a cosmetic layer — in FPC, it directly influences mechanical performance.

8. Final Thoughts

In flexible PCB manufacturing, ENIG and hard gold are not interchangeable options.

ENIG is generally preferred for SMT and signal integrity, while hard gold is reserved for mechanical contact durability.

Selecting the correct finish early in the design phase reduces reliability risks and avoids costly redesign during mass production.

If you are unsure which surface finish fits your application, reviewing the mechanical environment and expected bending cycles is the best starting point.

FAQ

1. Is ENIG suitable for dynamic flex applications?

ENIG can be used in flexible PCB, but it is generally not recommended in high dynamic bending areas.

The reason is the nickel layer underneath the gold. Nickel is significantly less ductile than copper, and repeated flexing can cause:

Micro-cracks in the nickel layer

Stress concentration at pad edges

Reduced bending cycle life

For static flex applications (one-time installation bend), ENIG is usually acceptable.For dynamic flex applications (continuous movement), surface finish should be kept outside the bending zone whenever possible.

Proper bend radius design and plating area control are critical.

2. Does hard gold reduce flexible PCB life?

Hard gold itself is not the main issue — the thick nickel layer required for electroplating is.

Compared to ENIG, hard gold typically involves:

Thicker nickel plating

Higher internal plating stress

Increased local stiffness

In dynamic bending conditions, these factors can:

Reduce flex endurance

Accelerate crack formation at transition areas

Increase risk of delamination

If hard gold is required (for example, gold fingers), it should be:

Located outside bending areas

Mechanically supported with stiffeners

Designed with smooth copper transitions

When properly placed, hard gold does not significantly impact overall board life.

3. Can ENIG be used for gold fingers?

Technically yes — but in most cases, it is not recommended for high-cycle insertion connectors.

ENIG provides:

Good corrosion resistance

Good solderability

However, it has thin gold layer and Limited wear resistance.

For applications requiring repeated insertion and removal (edge connectors, card interfaces), hard gold is the industry standard because of its superior abrasion resistance.

ENIG may be used for:

Low insertion cycle applications

Signal pads that are not subject to mechanical wear

For connector-grade reliability, electroplated hard gold remains the preferred solution.

Comments