Advanced Manufacturing Techniques of FPCB for CCM(Compact Camera Module)

- Flex Plus Tech team

- Nov 20, 2023

- 2 min read

Updated: Mar 3, 2025

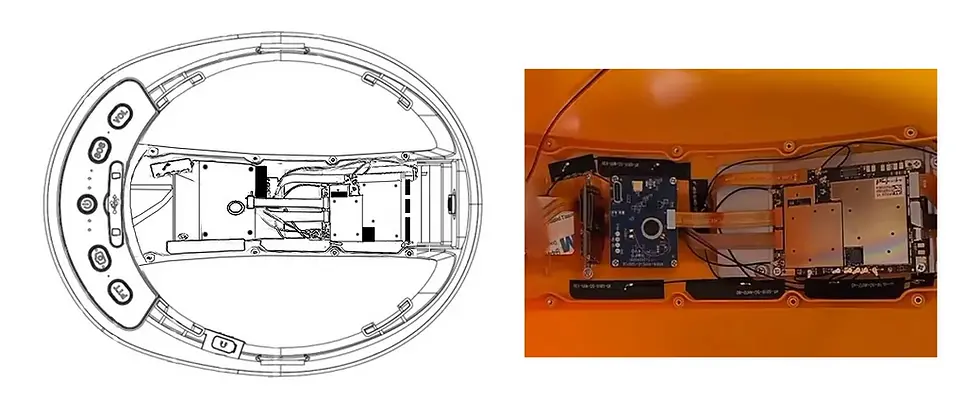

The breakdown of compact camera module, the FPC inside the CCM.

CCM, Short for Compact Camera Module.

CCM comprises four main components: Sensor, Lens, DSP, FPCB (Flex PCB as connector, also, as FPC Frame).

The crucial components determining the quality of a camera are the lens, image processing chip (DSP), and sensor

translate from demo picture

镜头, Lens

镜座, Lens Holder

电容, Capacitor

电阻, Resistor

CMOS感应器, CMOS Sensor

How it works

Light gathered through the lens is converted into electrical signals by the CMOS or CCD integrated circuit. These light signals are then processed into digital image signals by the ISP, internal Image Signal Processor and output to the DSP, Digital Signal Processor for further processing, resulting in standardized image signals such as GRB, YUV, etc.

Flex Plus Key Manufacturing Technical Features of FPCB for CCM(Compact Camera Module)

1.High Precision of Solder Pads for BGA Structure

The minimum solder pad size in BGA mounted on FPCB for CCM(Compact Camera Module) can be achieved with precision as small as 0.2mm. The solder pad position accuracy controlled within ±0.05mm.

2.High Uniformity of Copper Plating in Vias High Precision in Alignment of Double-Sided Circuits.

The surface uniformity of copper plating can achieve ±2um, and the copper on vias is maintained at ≥12um, fully meeting the reliability requirements of FPC.

3.High Precision in Alignment of Double-Sided Circuits

The alignment tolerance of double-sided circuits is within ±0.07mm.

4.Exceptional Performance Assurance for FPC

Soldering rate on solder pads ≥98%, ensuring excellent soldering performance

SMD design adopted in critical pad areas, ensuring strong solder pad adhesion

Impedance value controlled within ±8% tolerance.

6 years FPCB support to Optical Industry Experience and Partners

Flex Plus, since its inception in early 2016, has cultivated a profound association within the mobile Optical industries. Its steadfast collaborations with leading Camera Module corporations have significantly fortified our expertise in FPCB manufacturing. This enduring partnership has not only contributed to our comprehensive understanding of Flex PCB but has also facilitated an extensive network of reputable suppliers and Camera module collaborators: Sunny Omnilight Technology, Lox Visions, OFilm, Q Tech and etc.. With a decade's worth of experience, Flex Plus stands as a trusted and knowledgeable company, adept in catering to the diverse needs of Flexible Printed Circuit solutions.

For FPC requests with Gerber drawings/CAD files, please contact:

info@flexplusfpc.com (Market)

gm02@fpc-plus.com (Factory)

Experience the convenience of working with Flex Plus.

You can also reach us on WhatsApp at +86 184 5004 5626

Comments