Flex PCB Solder Defects: Twist, Bending, and Weld Leg

- Flex Plus Tech team

- 3 days ago

- 2 min read

Flex PCB solder defects are common in flexible circuits because the boards bend, twist, and warp more easily than rigid PCBs. These deformations can cause uneven soldering, misaligned components, and weak joints. The main causes are twist and bending of the flexible PCB and weld-leg (pin leg) issues. Understanding these factors is key to reliable assembly.

Twist and Bending

Flexible PCBs are thin and soft, so small movements during handling, printing, or reflow can cause twist or bending. Even minor deformations can create problems:

Pads may sit at different heights

Component pin legs may not sit flat on solder paste

Solder joints can have uneven thickness, leading to open or cold joints

Optical components like LEDs or sensors can tilt

How to minimize twist and bending effects:

Use rigid carriers, stiffeners, or vacuum plates to keep the board flat

Check and maintain flatness before placement (<0.2 mm warpage)

Avoid rapid temperature changes during reflow

Support ultra-thin flexible PCBs with panel frames or edge rails

Twist and bending often lead to weld-leg problems in component placement.

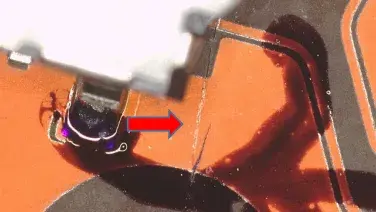

Weld Leg — Pin Behavior on Uneven Surfaces

A weld leg is the metal terminal or pin that contacts solder paste. On a warped or uneven FPCB, different pin legs land at different heights, which can cause:

High-sitting legs → no solder → open circuit

Low-sitting legs → excess solder → bridging

Components rocking during reflow → skew or tombstoning

Fine-pitch ICs particularly sensitive to uneven pin placement

Preventing weld-leg defects:

Keep the flexible PCB board flat during stencil printing and placement

Check coplanarity of pin legs for sensitive components

Adjust stencil paste distribution for outer pads

Maintain uniform adhesive thickness in COB assembly

Factor | Risk if Ignored | Mitigation |

Twist & Bending | Uneven pad contact, open joints, component tilt | Flat support, stiffeners, careful handling, controlled reflow |

Weld Leg / Pin Leg | Open joints, bridging, skew, tombstoning | Coplanarity checks, stencil paste adjustment, adhesive height control |

Common Flex PCB Solder Defects

Typical defects resulting from twist, bending, and weld-leg issues include:

Pad lifting — pads detach from the PI substrate due to stress

Cold solder joints — poor wetting from uneven paste or rapid cooling

Solder bridging — caused by uneven pad heights

Component shifting — soft FPC allows movement during reflow

Cracked solder joints — bending during assembly or in-field use

Tips to Reduce Solder Defects

Design and Layout:

Avoid placing solder joints in high-bending areas

Add stiffeners under heavy or sensitive components

Use reasonable pad sizes to reduce lifting

Handling and Placement:

Keep flexible circuits flat during transport and assembly

Use trays, plates, or support structures to stabilize boards

Optimize solder paste printing and volume

Reflow and Assembly:

Adjust reflow profiles for PI and copper stack-ups

Ensure components are properly aligned and coplanar

Monitor soldering quality and perform bend-cycle or pull tests as needed

Summary

Mechanical stability is critical for flex PCB solder quality. Controlling twist, bending, and weld-leg behavior ensures consistent solder joints, reduces rework, and improves long-term reliability for SMT and COB assemblies.

Comments