Flex PCB for Pressure Sensors

- Flex Plus Tech team

- Jan 20, 2025

- 3 min read

Updated: Apr 22, 2025

You know, nowadays, there's a growing need for smart electronics and industrial sensors. That's why flex PCBs are being used more and more in pressure sensors. They're especially great when you pair them with pressure-sensitive materials. It really boosts the sensors' performance, making them more flexible, accurate, and dependable. In this article, we'll dive into a specific example of a pressure sensor design and check out the main benefits and uses of flex PCBs in these sensors.

Design and Features of Flex PCB for Pressure Sensors

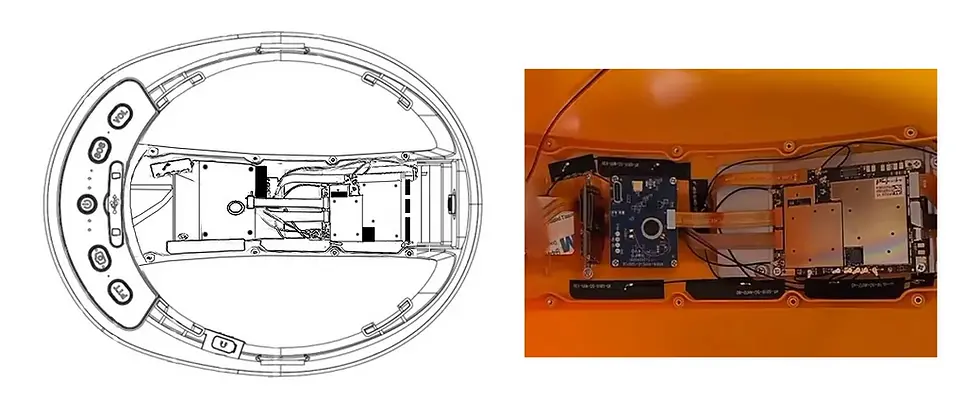

The image clearly shows that this pressure sensor features a circular sensing area and a long-tail design. This structure, combined with the ability to design flex PCB, makes the sensor particularly suitable for compact devices and irregular surfaces, allowing for efficient pressure detection in limited spaces.

Key Design Features:

Circular sensing area: The sensing area of the sensor can be made according to customer requirements. This means it can precisely detect any pressure changes on its surface. Such a design gives it high sensitivity and precision, which is perfect for things like touch buttons or switches.

Long Tail Design: The long tail part is where the electrical connection happens. It makes it really easy to connect the sensor to external electronic systems. This design is great for devices that need cables or wires to transmit signals because it ensures a simple connection process.

Flexible Material: The sensor's base material is a flexible circuit board, typically made from polyester films, which enables the sensor to conform to uneven or curved surfaces. This flexibility makes it particularly suitable for applications in wearable devices, touch screens, or various electronic devices.

How Pressure Sensors Work and Their Applications

This flexible PCB pressure sensor works on the resistance-change principle. When you put pressure on the sensing area, the sensor’s resistance changes, and this change is sent through the electrical connections as a signal that can be measured. Thanks to this principle, the sensor can accurately measure the applied pressure and convert it into an electrical signal that other devices can process. With its flexible PCB application, the sensor can be seamlessly integrated into various electronic systems, offering enhanced adaptability and durability for different use cases.

Applications:

Touch Sensing Tech: This sensor is perfect for all kinds of touch stuff, like buttons, switches, and control panels. It's super flexible and precise, so it's used all over the place in smartphones, tablets, and other touchy gadgets.

Human-Machine Interface (HMI): In today's electronics, pressure sensors are key for human-machine interfaces. The flexible PCB sensor can be built into control panels and input devices, making for a really smooth and easy-to-use experience, especially in wearable tech and smart home stuff.

Advantages of Fle PCB Sensor

High Flexibility: Flexible PCBs are super bendy and can fit onto bumpy or curved surfaces. That's why they're great for devices with limited space, like wearables, car electronics, and industrial control systems.

Precision and High Sensitivity: These sensors use pressure-sensitive materials, so they can pick up even tiny changes in pressure. That's crucial for stuff that needs really accurate monitoring.

High-Temperature Resistance and Stability: The sensor can handle hot environments, making it perfect for industries like industrial automation, cars, and medical devices.

Electromagnetic Interference (EMI) Resistance: The flexible PCB sensor's design helps cut down on electromagnetic interference, so it works reliably in tricky electronic settings.

Conclusion:

This Flex PCB pressure sensor is super flexible, precise, and dependable, making it awesome for all sorts of advanced uses. Whether it's for touch sensing in smart gadgets or accurate input in human-machine interfaces, it performs really well. As we keep making smaller and smarter electronics, flexible printed circuit boards will be super important for new pressure sensor applications, pushing tech advancements across different industries.

Comments