Bestückung flexibler Leiterplatten

Suchen Sie einen Hersteller hochwertiger Flex- und Rigid-Flex-Leiterplatten? Flex Plus bietet sowohl inländische (China) als auch internationale Flex- und Rigid-Flex-Leiterplattenmontage zu günstigen Preisen an. Mit Flex Plus erreichen Sie schnellere Markteinführungen und erzielen einen höheren ROI. Überzeugen Sie sich noch heute von Ihrem Flex-PCB-Auftrag, indem Sie uns Ihre Gerber-Dateien und/oder Spezifikationen für Ihr nächstes Projekt zusenden.

_JPG.jpg)

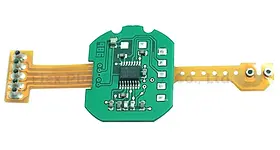

SMT-Bestückung

Surface Mount Technology (SMT) ist ein Verfahren zum Aufbau elektronischer Schaltungen, bei dem die Komponenten direkt auf flexiblen Leiterplatten (FPCBs) montiert werden. Diese Technik ermöglicht im Vergleich zur Through-Hole Technology (THT) kleinere, kompaktere und leistungsstärkere elektronische Baugruppen.

.jpg)

THT-Bestückung

Die Durchsteckmontage (THT) ist eine Methode zum Aufbau elektronischer Schaltungen, bei der die Komponenten montiert werden, indem ihre Anschlüsse durch in flexible Leiterplatten gebohrte Löcher gesteckt und auf der gegenüberliegenden Seite festgelötet werden.

_JPG.jpg)

SMT- und THT-Mischbestückung

Mixed Assembly ist ein Verfahren, das Oberflächenmontage (SMT) und Durchsteckmontage (THT) bei der Montage von flexiblen Leiterplatten kombiniert. Dieses Verfahren eignet sich besonders für komplexe Leiterplatten mit unterschiedlichen Komponenten und nutzt die Effizienz der SMT und die starken mechanischen Verbindungen der THT.

Hersteller von flexiblen Leiterplatten

Flex Plus – Ihr zuverlässiger Partner für die komplexe Bestückung flexibler Leiterplatten. Unser spezialisiertes Verfahren gewährleistet präzises Löten und hochwertige Ergebnisse für Elektrofahrzeuge, Medizintechnik, Luft- und Raumfahrt, Industrieanlagen und Konsumgüter.

Flex- und Rigid-Flex-Leiterplattenmontage (FPCBA)

Entdecken Sie unsere FPCB-Lösungen für eine vielseitige und effiziente elektronische Montage in Ihren Produkten

.webp)

.webp)

.webp)

Component Sourcing with Flex PCB Assembly

Working on a new product often means chasing down dozens of parts from different vendors. At Flex Plus, we take that hassle off your plate. Along with flex PCB assembly, our team can also handle component sourcing for your project. We work with established suppliers to make sure you get the right parts—on time and within budget.

.webp)

.webp)

.webp)

.webp)

.webp)

.webp)

.webp)

.webp)

Why customers rely on our FPCB assembly service:

-

Everything under one roof – component sourcing, FPCB assembly, testing, and final delivery.

-

Better pricing – our supplier network helps cut costs without cutting corners.

-

No delays – verified parts and smooth logistics keep your schedule on track.

-

Scalable support – whether you need a small prototype run or mass production.

Instead of juggling multiple vendors, you get a single partner who manages the details and keeps things moving. That way, you can focus on building products that reach the market faster.

FPCB Assembly Process

Flexible PCB assembly follows a step-by-step process to ensure reliability and high performance. From incoming material inspection, include careful checks of bare flex circuit boards and electronic components. Next, paste the solder onto the pads, and using automated pick-and-place machines to place the components . and then go through reflow soldering to secure the parts. Afterward, automated optical inspection (AOI) is carried out to detect any defects. If the design includes through-hole parts, they are inserted and soldered either by wave soldering or manual soldering. Once assembled, the boards are tested for electrical performance, followed by final inspection and cleaning. Finally, the completed flexible PCB assemblies are packaged and shipped to customers.

Beherrschung der Flex-PCB- und FPCB-Montage:

Technische Herausforderungen mit Flex Plus meistern

Bending and Flexibility Optimization

Ensuring the FPCB's bending capability without compromising electrical performance can be challenging. At Flex Plus, we employ advanced material selection and design optimization techniques. By utilizing flexible substrates with suitable reinforcement layers and controlled bending radii, we achieve outstanding flexibility while maintaining reliable electrical connections.

Moisture Absorption Prevention

FPCBs' susceptibility to moisture absorption during transportation and storage can lead to defects like delamination and blistering during reflow soldering. To counter this, we implement a precise pre-baking process, removing moisture before assembly. This proactive approach ensures the long-term reliability and performance of our FPCB.

High-Quality Soldering

Maintaining reliable solder joints on flexible substrates is critical for long-term performance, especially during repeated flexing. Flex Plus utilizes high-quality solder paste, precise reflow soldering profiles, and proper component trimming to ensure robust and durable solder connections, enhancing the overall reliability of our Flex PCB assembly.

Precise Component Mounting and Alignment

The lack of rigidity in FPCB boards can challenge precise component placement and alignment. Flex Plus employs state-of-the-art pick-and-place machines with optical positioning systems. Additionally, our specialized carrier fixtures facilitate accurate component mounting on the flexible substrate, ensuring optimal electrical performance.

Comprehensive Inspection and Testing

Inspecting and testing FPCB can be more challenging than rigid PCBs due to their non-planar surfaces. We have developed specialized ICT and FCT fixtures to perform thorough inspections. Our visual inspection with magnification and implementation of advanced AOI systems ensure early detection and correction of any defects, guaranteeing the highest quality end products.

Flex Plus - Your Trusted Flex PCB Assembly Partner

With our expertise in flex PCB assembly and a commitment to overcoming technical challenges, Flex Plus stands as a trusted partner for clients seeking cutting-edge solutions. We excel in EVs, medical devices, aerospace, industrial machines, and consumer products, offering reliable and high-performing FPCB assemblies tailored to meet diverse application needs. Experience the difference with Flex Plus and unlock the true potential of FPCB technology for your projects.

.webp)