What is flex pcb connector?

- Flex Plus Tech team

- Oct 15, 2024

- 2 min read

Updated: Dec 24, 2024

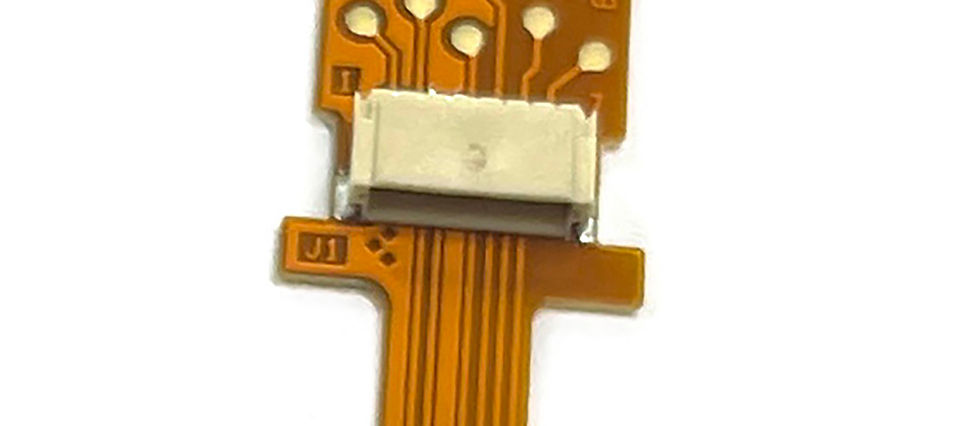

Flex PCB connector or FPC connector, in simple terms, is a component used to connect a flexible printed circuit board to a rigid PCB or other device. This type of connector is very useful, especially in situations where frequent bending and connection are required, such as smartphones, tablet computers, and other portable devices, used to connect LCD displays and drive circuits.

With the development of technology, the types and uses of flex PCB connectors are increasing, bringing more choices and possibilities to the design and manufacture of electronic equipment.

3 Types of Flex PCB Connectors

Shrapnel flex PCB connector: This connector is connected by the spring and flex PCB board. It has a simple structure, is easy to use, and has a stable connection. You’ll often find these in consumer electronics like smartphones and tablets.

Pin flex PCB connector: pins connect with the conductive holes on the flex PCB board. This type of connection is really sturdy and ensures stable signal transmission, making it perfect for high-speed and high-stability applications, like data transfer equipment and communication devices.

Plug-in flex PCB connector: This connector can be repeatedly plugged in and out like a socket, which is very convenient to use. It is suitable for occasions where flex circuits need to be replaced or repaired frequently, such as test equipment and repair tools.

Application fields of flex PCB connectors

FPC connectors are everywhere. You’ll find them on electronic devices, smartphones, tablets, and monitors. In smartphones, they connect the screen, camera, and buttons. In tablets, they link the touch screen, battery, and speakers. They’re even used in high-end areas like automotive electronics, medical equipment, and aerospace—definitely an important player.

Benefits and drawbacks of flex PCB connectors

Flexible PCB connectors still have many benefits like providing a stable mechanical linkage between flexible circuit board and rigid board, high transmission rate, takes up little in terms of space occupied among other factors. On the other side, it also has some disadvantages, for example, high production costs, different connectors may be soldered on flex PCB using SMT or THT processes. Hence, every time we decide to choose what kind of connector we are to use; we need to make all the decisions holistically considering the present conditions and everybody’s requirements.

Future development trend of flex PCB connectors

Besides the further improvement of technology and enlargement of components, the flex PCB connector's future development trend is also obvious. Flexible electronic technology development on the one hand enables the FPC connector's performance to be improved better, such as improved connection stability, and lower transmission latency. One of the factors, that affects the design of flex PCB connectors, is the no localization of the Lead-free components.

Summary

We also have an understanding that a flex PCB connector is one of the critical parts of an electronic device with extended application and benefits. They are able to meet the performance level just fine in the process of choosing and way of applying the parts that are appropriate.

Flex Plus, as a professional flex PCB manufacturer, can provide customized services to our customers. If you have any questions, feel free to contact us.

Comments