How Heavy Copper Flexible PCB Work ?

- Flex Plus Tech team

- Aug 14, 2025

- 3 min read

If you’ve ever worked on a high-power electronics project, you know the challenge—getting the current capacity you need without turning your PCB into a miniature space heater. That’s where heavy copper flexible PCB step in.

These boards combine the muscle of thick copper conductors with the agility of a flexible substrate. The result is a circuit that can carry serious current, handle heat like a pro, and still bend or fold to fit into tight, unconventional spaces. From EV battery systems to rugged military gear, heavy copper flex circuits are finding their way into designs where failure is not an option.

What is a Heavy Copper Flexible PCB?

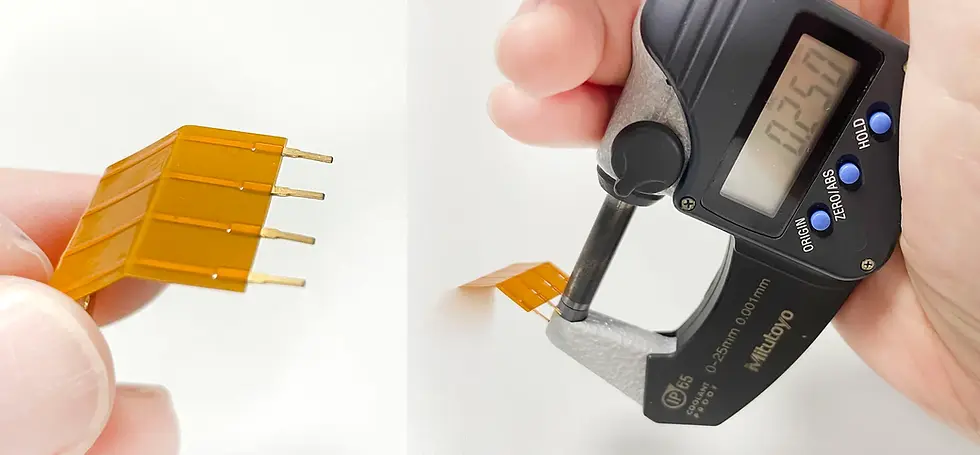

A standard flexible PCB usually has copper around 1 oz (35 µm) thick. With heavy copper flex circuit boards, we’re talking 3 oz (105 µm) or more. That extra copper mass gives you:

Higher current-carrying capacity

Better heat spreading

A tougher, more durable circuit

They’re a go-to choice for applications like power converters, aerospace controls, defense electronics, and industrial automation—anywhere you need high performance in a small footprint.

Understanding Heavy Copper in Flex PCB

Heavy copper isn’t just “more copper.” It changes how your board behaves. Thicker copper traces mean lower resistance, higher ampacity, and more efficient heat management. IPC standards classify anything over 3 oz as “heavy copper,” and if you go above 20 oz, it’s considered “extreme copper.”

In flexible printed circuit boards, heavy copper strikes a balance—you get the strength and electrical performance without completely giving up flexibility.

How Heavy Copper Flexible PCB Work

Copper Thickness and Current Capacity

The thicker the copper, the more current it can carry without excessive heating. That’s critical in high-power designs like DC-DC converters, motor drivers, or BMS boards in EVs.

Flexible Substrate and Mechanical Strength

The polyimide or PET film underneath provides flexibility. But as copper gets thicker, you lose some bendability. That’s why smart layouts concentrate thick copper where it’s needed and keep flex zones lighter.

Heat Dissipation Performance

Heavy copper acts like a built-in heatsink. It pulls heat away from hotspots and spreads it evenly, cutting down on the need for bulky thermal management parts.

The Impact of Heavy Copper on Flexibility

Here’s the trade-off: more copper equals less bend. The minimum bend radius grows, and you can’t flex the board as sharply without risking cracks. Good designs put bend areas away from heavy copper zones so the PCB can still move where it needs to.

Key Advantages

High current handling without overheating

Superior reliability under vibration, shock, and temperature extremes

Ability to replace multiple rigid boards and connectors with one integrated design

Better heat management, leading to longer component life

Why Use Heavy Copper?

If you need a printed circuit board that can survive heavy current, tough environments, and long lifespans, heavy copper flexible boards are worth the investment. They reduce interconnect points (and failure points), handle mechanical stress better, and often let you simplify your overall design.

Design Considerations: Line Widths and Spacing

Thicker copper changes the design rules. You’ll need:

Wider traces for manufacturability

More spacing to allow for clean etching

Thoughtful impedance control if you’re routing high-speed signals

Thermal reliefs on pads to make soldering easier

Drawbacks of Heavy Copper in Flex PCB

It’s not all upside—there are a few watch-outs:

Higher cost due to extra copper and more complex processing

Reduced flexibility compared to standard FPCs

Longer lead times because plating and etching take more steps

Knowing these helps you set realistic budgets and timelines.

Manufacturing Heavy Copper Flexible PCB

Etching and Plating Process

Heavy copper usually requires multiple plating cycles and careful etching to keep traces clean and defined.

Adhesion Between Copper and Flexible Substrate

With thick copper, adhesion is critical. Surface finishes like ENIG or OSP help maintain strong bonds and protect against oxidation, especially in high-humidity or high-temperature environments.

Best Practices for Implementing

Keep a generous bend radius in heavy copper areas

Use selective copper thickness—heavy where you need it, light where you don’t

Add thermal vias under hot components

Work with a manufacturer experienced in both heavy copper and flexible PCB processes

Applications

EV battery management systems

Aerospace flight controls

Military communication gear

High-power industrial controllers

Choosing the Right Flex PCB Supplier

Not all PCB suppliers can handle heavy copper flex builds. Look for:

Proven track record with thick copper PCB fabrication

Precision etching and plating capabilities

Strong quality systems (IPC Class 3, UL, RoHS)

In-house engineering support to optimize your design

Conclusion

Heavy copper flexible PCB give you a rare combination—high electrical capacity, durability, and flexible form factors. They’re the smart choice for demanding, high-power designs that can’t afford failure.

If your project needs power, reliability, and smart design, we’re here to help.

Let’s talk about your next build: https://www.flexplusfpc.com

Comments