Can You Make a FPC Board at Home?

- Flex Plus Tech team

- Jun 19, 2025

- 2 min read

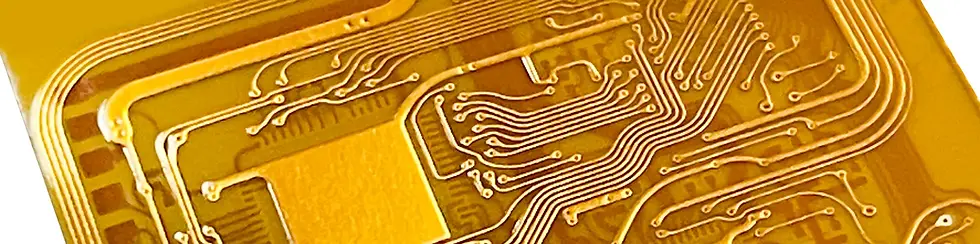

Creating a FPC board (Flexible Printed Circuit board) at home might sound appealing to electronics enthusiasts, but is it actually feasible? While DIY PCB-making is common, the flexible counterpart presents unique challenges that most hobbyists aren’t prepared for.

What Is a FPC Board?

A FPC board is a flexible circuit designed to fit non-flat or dynamic mechanical environments, often used in wearables, sensors, and compact electronics. Unlike rigid PCBs, FPCs are made with ultra-thin polyimide substrates and require high precision in etching, drilling, and layer alignment.

Can You Make a FPC Board at Home?

Technically, yes — but realistically, it’s very difficult.

While some experienced makers and researchers have succeeded in crafting basic FPC prototypes using DIY tools, home environments usually lack:

- UV exposure precision

- Controlled etching conditions

- Laser or micro-drilling capabilities

- Cleanroom-level dust and wrinkle control

Moreover, flexible materials like PI film and FCCL (Flexible Copper Clad Laminate) are hard to source and require special handling.

What Makes FPC Harder Than PCB?

Feature | Rigid PCB | FPC board |

Substrate | FR4 | Polymide |

Handling | Easy | Pone to warping |

Exposure Process | Tolerant | Require perfect alignment |

Drilling | Hand-drill acceptable | Needs laser or micro drill |

Success Rate | High | Low for home users |

The tolerances for FPC board manufacturing are far tighter, which means even small deviations can lead to short circuits, broken traces, or failed soldering.

Why Choose a Professional FPC Manufacturer?

If you need a reliable, production-ready custom FPC board, it’s far more effective to partner with a trusted flexible PCB manufacturer like Flex Plus.

Flex Plus: Your Custom FPC Board Expert

At Flex Plus, we specialize in the design and mass production of custom flex PCBs, from simple single-sided flex PCB to multi-layer flex PCB and complex FPC assemblies. Our services include:

- Rapid prototyping

- Laser cutting and drilling

- Coverlay and stiffener integration

- SMT assembly on flexible substrates

- ISO and RoHS compliant quality systems

With our in-house engineering support and precision manufacturing, you can get production-grade FPCs in days, not weeks.

Final Thoughts

While making an FPC board at home is a fascinating challenge, it’s best suited for highly skilled DIYers or academic labs with the right tools. For practical, scalable, and high-reliability results, working with a manufacturer like Flex Plus ensures your design becomes a reality without the trial and error.

Ready to build your custom FPC board the right way? Contact Flex Plus for a fast quote and expert consultation.

Comments